Product descriptions from the supplier

Product Overview

CK61110-1.5 meters CNC lathe

1. Large aperture spindle, good rigidity, compact structure . 2. Electromechanical and hydraulic integration design, reasonableoverall layout, easy to repair and maintain . 3. Can process various shaft and disc parts, can turn various threads, arc cones andinternal and external complex curved surfaces of the rotary body . 4. The sliding guide rail adopts medium frequency quenching,the hardness is more than 50 degrees, and the joint surface of the drag plate and the bed is pasted. 5.The bed design has been improved to make it easy to drain and remove chips.

Product Paramenters

|

Technical parameters of CK61110(CAK110) high-quality CNC lathe

|

|||

|

Items

|

Unit

|

CK61110 Standard

|

CK61110 High configurationHigh configuration

|

|

Maximum swivel diameter of the bed

|

mm

|

1100mm

|

|

|

Maximum swing diameter on the tool holder

|

mm

|

780mm

|

|

|

Maximum workpiece length

|

mm

|

1000、3000-6000

|

|

|

Spindle through-hole diameter

|

mm

|

105.A2-11

|

105.A2-11 (The thickened spindle and bearing are enlarged)

|

|

CNC controller system

|

|

GSK980TDI controller system

|

|

|

Number of spindle speed stages

|

|

Hydraulic four-speed stepless speed regulation

|

|

|

Manual 4-speed spindle speed range

|

rpm

|

1st gear 17-70 rpm

2nd gear 38-155 rpm 3rd gear 75-293 rpm 4th gear 170-653 rpm |

|

|

Hydraulic 4-speed – spindle speed range

|

rpm

|

1st gear 20-80 rpm

2nd gear 50-200 rpm

3rd gear 100-330 rpm

4th gear 220-790rpm

|

|

|

Main motor power

|

KW

|

15KW

|

22KW

|

|

X-axis travel

|

rpm

|

550mm

|

|

|

Z-axis travel

|

rpm

|

1000、3000-6000

|

|

|

Rail width

|

rpm

|

700RC50° above

|

|

|

Maximum load-bearing

|

T

|

3T

|

|

|

Machine weight(Workpiece length/weight)

|

1000mm

|

5900kg

|

|

|

1500mm

|

6200kg

|

||

|

2000mm

|

6800kg

|

||

|

3000mm

|

7400kg

|

||

|

4000mm

|

8000kg

|

||

|

5000mm

|

9200kg

|

||

|

Standard chuck (optional)

|

Diameter 800mm four -jaw chuck

|

||

PRODUCT CONFIGURATION

CNC controller system

The standard control system is GSK980TDI system, which can adapt to efficient, high-speed and high-precision processing.

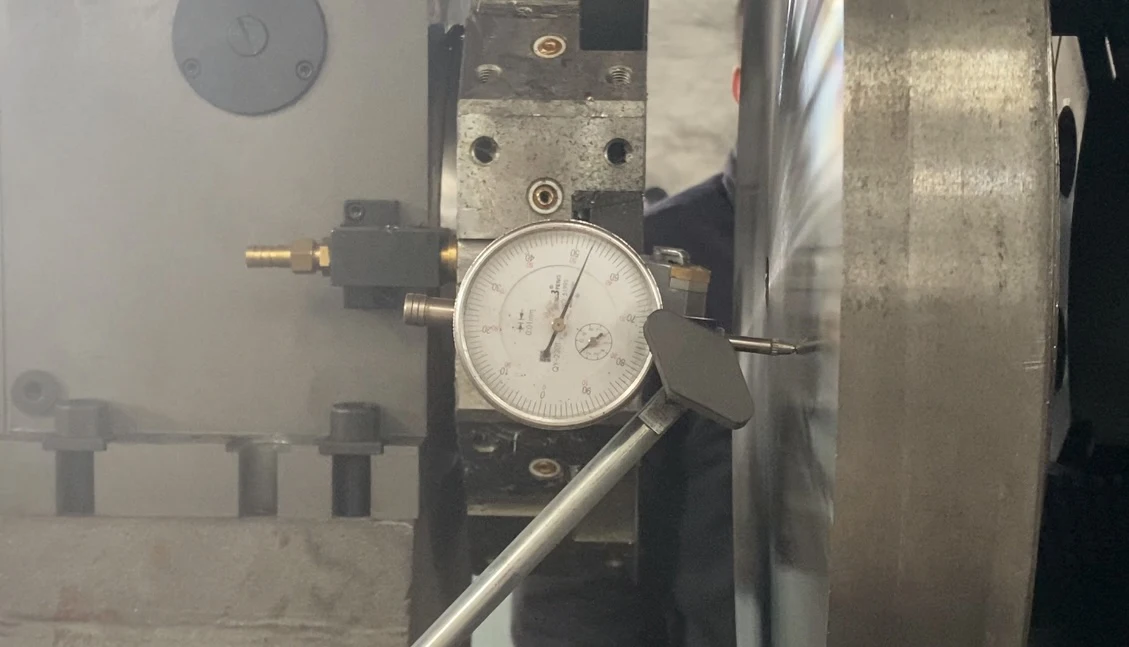

Guide rail

The sliding guide rail adopts medium frequency quenching, and the hardness reaches more than HRC50°.

Chuck

The standard machine tool chuck is a 800 mm four -jaw chuck, optionally configured as a 3-jaw or 4-jaw hydraulic hollow chuck.

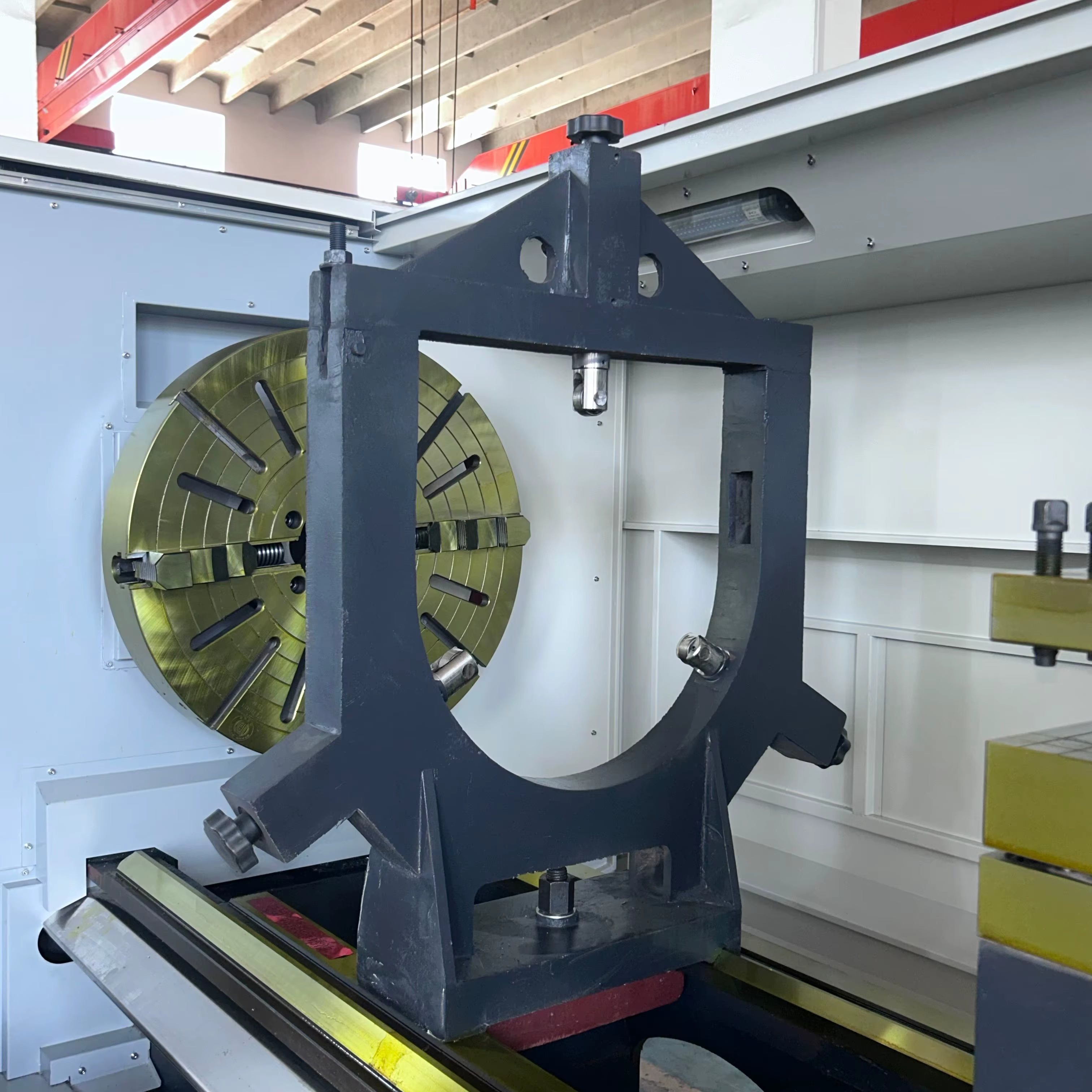

Steady rest

CK61110/CAK110 series CNC lathe, with 500mm hole steady rest. It can be customized according to your needs.

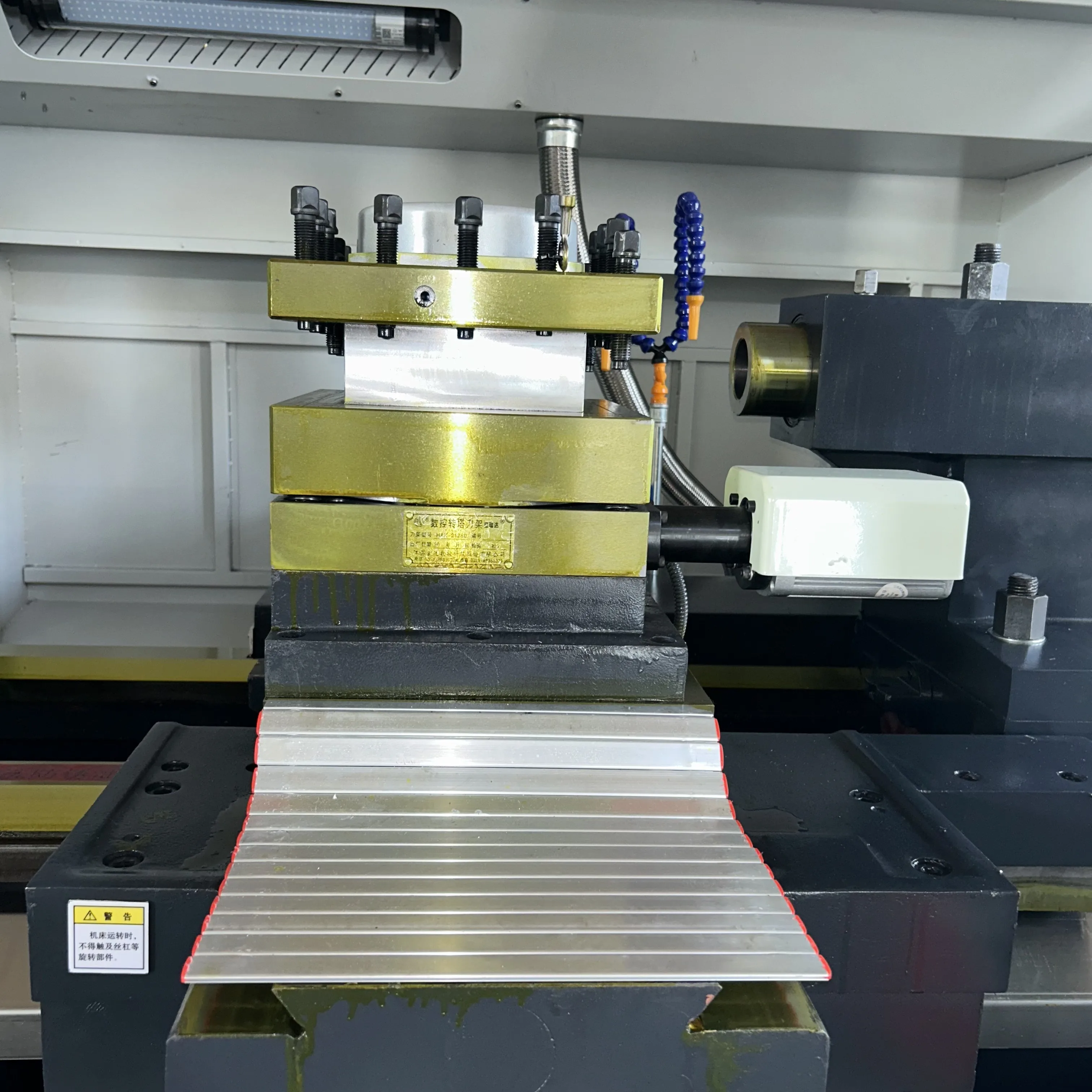

Four-station electric tool holder

This series of lathes adopts vertical four-station electric tool holder, which does not need to lift the cutter body when the four-station tool holder rotates, and has high sealing.

Ball screws

The 1-5 meter CNC lathe adopts ball screw, and the CNC lathe of 6 meters and above adopts precision rack, which can be selected according to customer requirements.

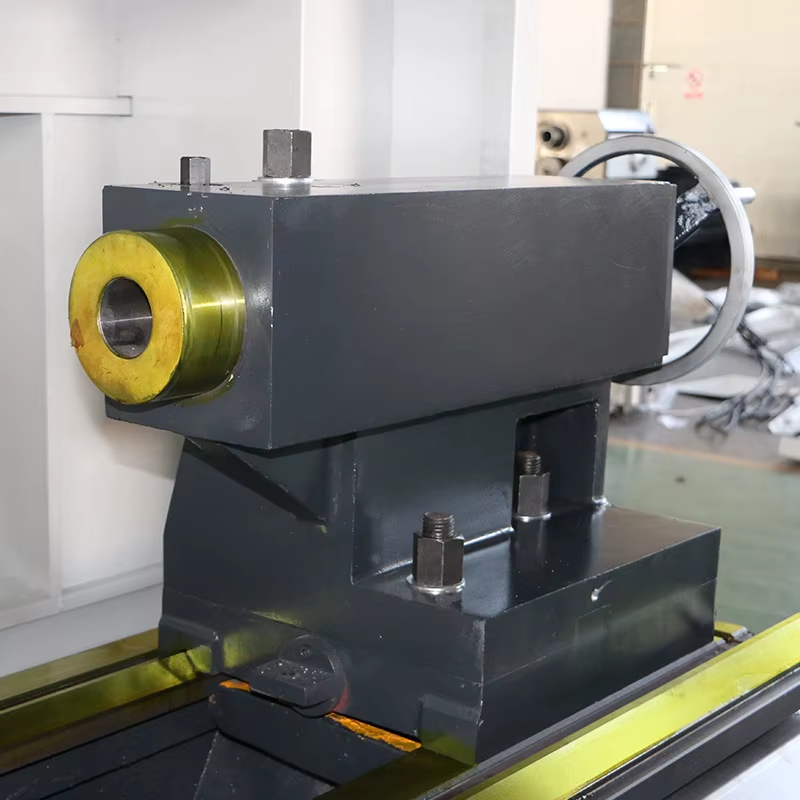

Tailstock

The tailstock consists of two parts: the upper body and the lower body. The upper body is equipped with a sleeve and a sleeve fast and slow movement mechanism. The tailstock sleeve cone hole of the machine is 6 on the Mohs scale and can be used with a Mohs 5 tip if attached to the cone sleeve. The tailstock of the machine tool has the characteristics of high precision, strong bearing capacity, long maintenance cycle and reliable work.

Product features

Processing demonstration

“Shenzhong” horizontal CNC lathe can turn and process a variety of parts of the inner and outer circle, end face, grooving, arbitrary cone, spherical and male, inch thread, tapered thread and other processes, suitable for the processing and production of large quantities of workpieces.

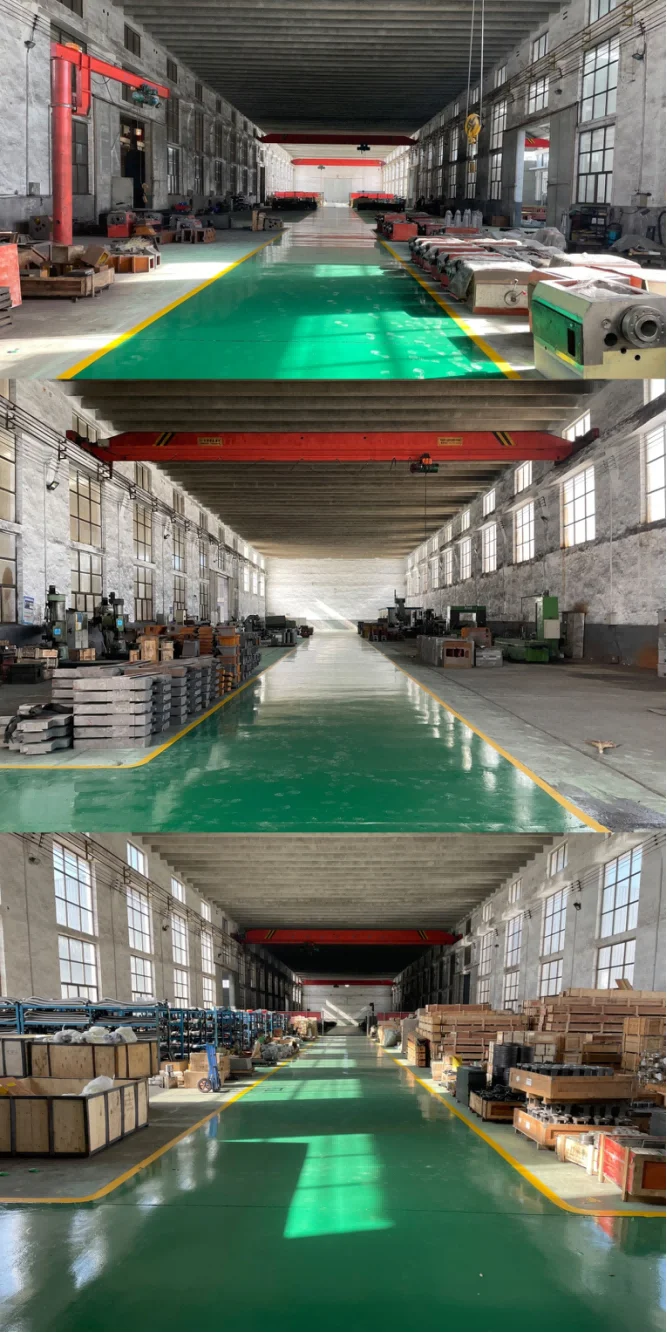

Company Profile

Product packaging

Exhibition

FAQ

Q1:Is our company the source manufacturer?

A1:Yes, our company has more than 25 years of production and R&D experience. OEM processing services are available.

Q2:How to order a CNC lathe?

A2:You can contact our sales directly on Alibaba, or you can contact us via WP:+8615532189840, or E-mail:yuto0406@outlook.com.

Q3:How about the quality of CNC lathes?

A3:Our CNC lathes use thickened beds, core components of well-known brands, and cooperate with the mechanical automation departments of local universities, so that the product quality can be guaranteed.

Q4:Do you provide after-sales service?

A4:Yes, we provide vending service, and can arrange technicians to come to your site to install, debug and repair the machine.

Q5:What is the address of the company?

A5:Mukou Industrial Zone, Xingjiawan, Renze District, Xingtai City, Hebei Province, China。We welcome you to visit the factory.

Reviews

There are no reviews yet.