Product descriptions from the supplier

Products Description

Products Description

Appearance size

Appearance size

Main performance characteristics:

1. High rigidity bed The CK6163 meter machine tool bed is made of high-quality cast iron with a reasonable layout of internal ribs. The bed is an integral type with a guide rail width of 550mm and good rigidity. The sliding guide rail adopts medium frequency quenching, with a deep quenching layer and a hardness of over HRC50 °. The joint surface between the drag plate and the bed is laminated with plastic. 2. Introduction to the main transmission The spindle of this series of machine tools adopts manual four speed stepless speed regulation, with a spindle speed of (1st gear 20-80 rpm/2nd gear 50-200 rpm/3rd gear 100-330 rpm/4th gear 220-790 rpm), high torque, and good reliability. Optional hydraulic four-speed stepless speed regulation, with the spindle speed regulation being 17-70 rpm in first gear, 38-155 rpm in second gear, 75-293 rpm in third gear, 170-653 rpm in fourth gear. The spindle bearing adopts high-precision bearings, ensuring smooth operation and high accuracy. 3. Feed system The Z-axis feed system of the machine tool uses a servo motor to drive the ball screw, while the X-axis feed system uses a servo motor to directly drive the ball screw through a coupling. The main screw of the machine tool adopts high-precision screw, and the lubrication points of the feed system are regularly lubricated by the centralized lubrication system. 4. Knife holder This series of lathes adopts a vertical four station electric tool holder. The tool body on the four station tool holder does not need to be lifted during rotation, eliminating the interference of coolant and cutting on the tool holder during rotation, and has high sealing performance. 5. Electrical system (1) CNC system and servo drive system The CNC numerical control system of machine tools adopts a wide range of numerical control systems, which can adapt to efficient, high-speed, and high-precision mechanical processing, and has the characteristics of convenient operation, complete functions, and high reliability. (2) The electrical cabinet adopts a fully enclosed type

Main technical parameters

Main technical parameters

|

Technical parameters of CK6163 series high-quality CNC lathe

|

||||

|

Maximum swivel diameter of the bed

|

mm

|

630

|

||

|

Maximum swing diameter on the tool holder

|

mm

|

350

|

||

|

Maximum workpiece length

|

mm

|

1000/1500/2000/3000/4000/5000

|

||

|

Spindle through-hole diameter

|

mm

|

105

|

||

|

CNC controller system

|

|

GSK980TDI controller system

|

||

|

Number of spindle speed stages

|

|

Hydraulic four-speed stepless speed regulation

|

||

|

Spindle speed range(Manual fourth gear)

|

r/min

|

1st gear 20-80 rpm/2nd gear 50-200 rpm/3rd gear 100-330 rpm/4th gear 220-790 rpm

|

||

|

Spindle speed range(Hydraulic fourth gear)

|

r/min

|

1st gear 17-70 rpm/2nd gear 38-155 rpm/3rd gear 75-293 rpm/4th gear 170-653 rpm

|

||

|

Main motor power

|

|

15KW

|

||

|

X-axis travel

|

mm

|

315

|

||

|

Z-axis travel

|

mm

|

1000/1500/2000/3000/4000/5000

|

||

|

Rail width

|

mm

|

550

|

||

|

Maximum load-bearing

|

T

|

2

|

||

|

Standard chuck (optional)

|

Diameter 400mm three-jaw manual chuck

|

|||

|

Total weight1000

|

T

|

4 tons (5% up and down)

|

||

|

Total weight1500

|

T

|

4.5 tons (5% up and down)

|

||

|

Total weight2000

|

T

|

4.7 tons (5% up and down)

|

||

|

Total weight3000

|

T

|

5.3 tons (5% up and down)

|

||

|

Total weight4000

|

T

|

6 tons (5% up and down)

|

||

|

Total weight5000

|

T

|

6.8 tons (5% up and down)

|

||

|

Machine size(Length * width * height)1000

|

mm

|

3300*1800*1800

|

||

|

Machine size(Length * width * height)1500

|

mm

|

3800*1800*1800

|

||

|

Machine size(Length * width * height)2000

|

mm

|

4300*1800*1800

|

||

|

Machine size(Length * width * height)3000

|

mm

|

5300*1800*1800

|

||

|

Machine size(Length * width * height)4000

|

mm

|

6300*1800*1800

|

||

|

Machine size(Length * width * height)5000

|

mm

|

7300*1800*1800

|

||

PRODUCT CONFIGURATION

PRODUCT CONFIGURATION

CNC controller system.

The standard control system is GSK980TDI system, which can adapt to efficient, high-speed and high-precision processing.

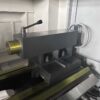

Chuck.

The standard machine tool chuck is a 400mm 3-jaw manual chuck that can be optionally configured according to your needs.

Center shelf.

The 300-well center frame is standard and can be customized to your needs.

Four-station electric tool holder.

This series of lathes adopts vertical four-station electric tool holder, which does not need to lift the cutter body when the four-station tool holder rotates, and has high sealing.

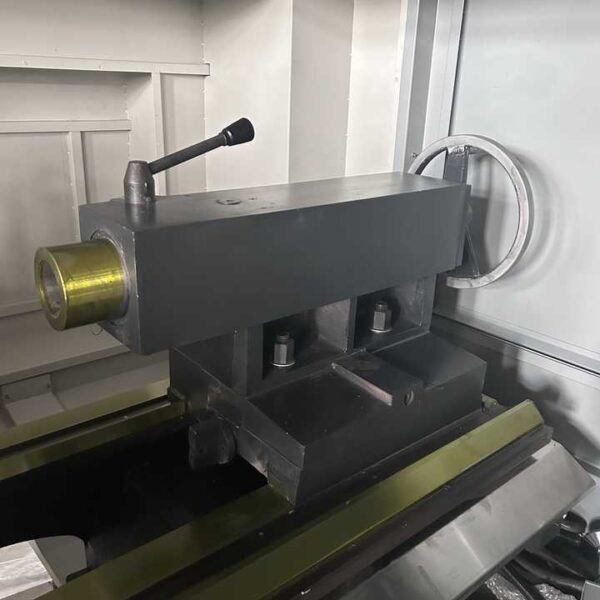

Manual tail stock.

The tailstock consists of two parts: the upper body and the lower body. The upper body is equipped with a sleeve and a sleeve fast and slow movement mechanism. The tailstock sleeve cone hole of the machine is 6 on the Mohs scale and can be used with a Mohs 5 tip if attached to the cone sleeve. The tailstock of the machine tool has the characteristics of high precision, strong bearing capacity, long maintenance cycle and reliable work.

Guide rail.

CK6163 machine bed is made of high-quality cast iron, the internal rib layout is reasonable, the bed adopts split type, the guide rail width is 550mm, and the rigidity is good. The sliding guide rail adopts medium frequency quenching, the hardening layer is deep, the hardness is above HRC50°, and the joint surface of the drag plate and the bed is pasted.

Company Profile

Company Profile

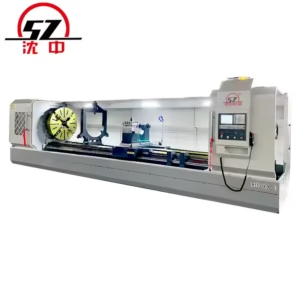

Xingtai Tianzuo Dingcheng Machinery Manufacturing Co., Ltd., formerly known as Renxian Huatai Machinery Factory, was founded in 1997. The main production of “Shenzhong” brand CK, CAK, CJK, CW series CNC amount horizontal ordinary lathes. The company covers an area of 40 acres, building organic processing workshop, machine tool body assembly workshop, CNC machine tool production workshop, production auxiliary facilities, R & D center and laboratory, with a total construction area of 16,000 square meters. We have about 500 workers and 40 engineers.Our team of engineers has rich experience in equipment manufacturing and process design. We can provide you with workpiece-based professional solutions quickly and freely. We can produce more than 1000 sets of CNC machine tools and equipment every year. Our CNC machine tools have been exported to more than 40 countries and got good feedback.

Product packaging

Product packaging

FAQ

FAQ

Q1:Can CK6163 high quality CNC heavy lathe be customized?

A1: Of course, if our standard configuration does not meet your needs, please let us know that we redesign and produce the machine to meet your needs.

Q2:What is the warranty period of CK6163 high quality CNC heavy lathe?

A2:The warranty period is one year, if the parts are damaged within one year, we will send them free of charge. Free online training or factoryTraining to ensure that you can use our products correctly. We can provide overseas paid installation, commissioning services.

Q3: What time are your working hours?

A3:We work online 24 hours a day, providing quotes and technical support at any time. Q4:Where is our factory located? How can I visit there?

A4:Our factory is located in Xingtai City, Hebei Province, China. We warmly welcome you to visit us.

Q5:How to get a quote?

A5:Please tell us the model you need or send us drawings of the workpiece, then we can recommend the most suitable products to you.We will give you the best offer within 24 hours. Q6:How to contact with you?

A6:My mobile/whatsapp: +86 15532189840; QQ:3553463275 ;Please send message to us, thanks in advance

Reviews

There are no reviews yet.